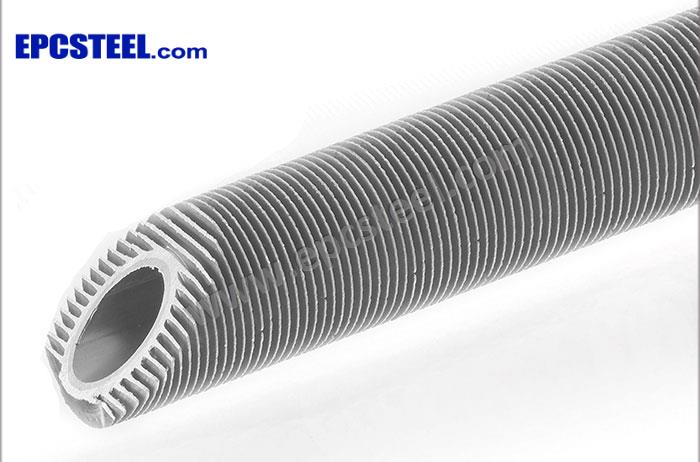

Extruded Finned Tube

(Bi-metallic Fin)

Application: High-efficiency extruded fin tube is for higher temperature applications giving complete and permanent atmospheric corrosion protection of the base tube. Using over 40% more aluminum than the other kinds of finned tube the extruded fin is very robust and resistant to mechanical damage, allowing the finned tubes to be cleaned without damage when be used in either steam or high-pressure water.

Upper limiting temperature: 300°C

Manufacture:

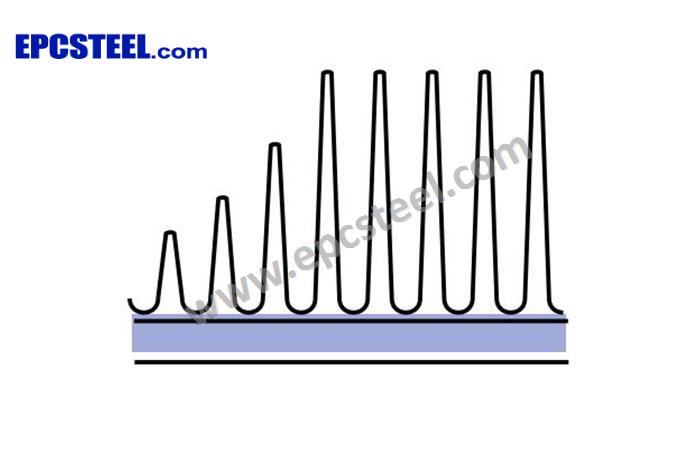

A carefully degreased core tube is fitted into an aluminium primary tube. This assembly is then fed into the triple-spindle finning head of the fin-extruding machine. Three special multi-disc packs extrude the aluminium tube into helical high fins while reducing the inner diameter to give firm

pressure contact with the core tube.

Reference Parameter:

Base Tube Diameter: 10mm-51mm

Base tube wall thickness: 1.65mm-3mm

Fin Thickness: 0.3mm-1.2mm

Fin Pitch: 2mm-15mm

Fin Height: 5mm-16mm

Base tube material:

Stainless steel, Carbon steel, Alloy, Titanium, Nickel, Copper etc.

Fin material:

Aluminum strip, Copper strip

Applications

The common application fields are:

1. Heat exchangers units for power plant (electric, nuclear, thermal and geothermal power plants);

2. High corrosive systems (condensers, evaporators, sea water desaltinations, fertilizing, urea systems, ammonia, gas, corrosive acids);

3. The petroleum, chemical and petrochemical industries;

4. The food processing and refrigeration industries;

5. Natural gas treatment.

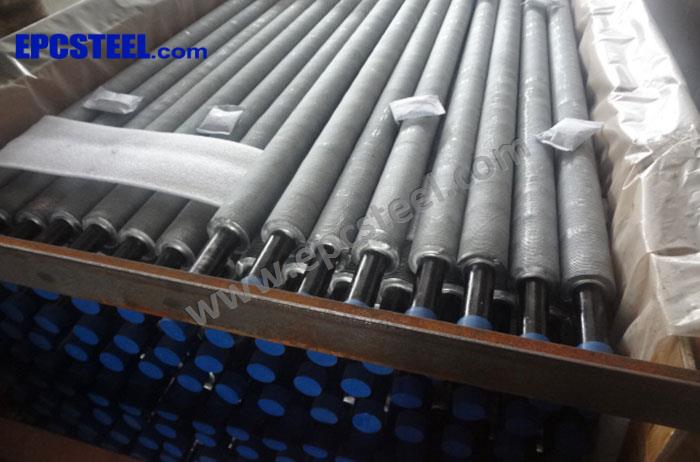

EPC Steel And Processing Group is specialized in processing of the extruded finned tube for many kinds of base tube and fin material. And the products have been exported to many countries and win good reputation. If you have any demand with the product, welcome to contact with us.