I. Advantages

Serrated fin tube is now more and more popular in the manufacturing of boiler, pressure vessel and other heat exchanger equipments. It has more advantages than other common solid fin tube, which mainly includes:

-

- Higher heat transfer coefficient. The serrate can make the gas flow across the fins freely, enhancing the turbulent motion and improving the heat transfer effect. Researches show that serrated fin tube’s heat transfer efficiency is about 15-20% higher than common solid fin tube.

- Reduce metal consume. Due to the higher heat transfer coefficient, for the same amount of heat, serrated fin tube is with less heat transfer areas, which help reduce the metal consume.

- Anti-ash-deposition and anti-scaling. Due to the serrate, it is very hard for the serrated fin tube to deposit the ash and scaling.

- It is more flexible to adapt to the changes of gas flow direction.

II. Production Process

With these advantages, serrated fin tube is now more and more popular among the customers. This article will help illustrate how to produce the serrated fin tube.

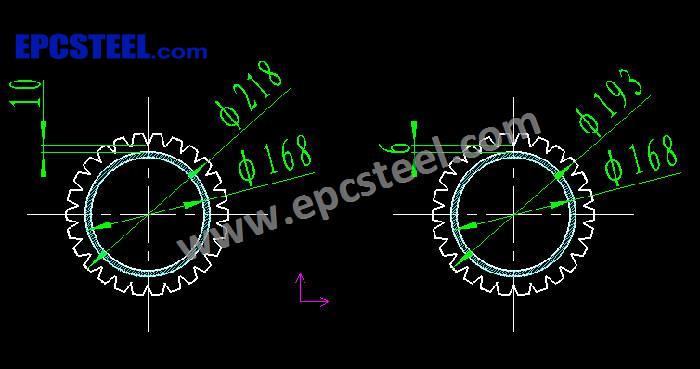

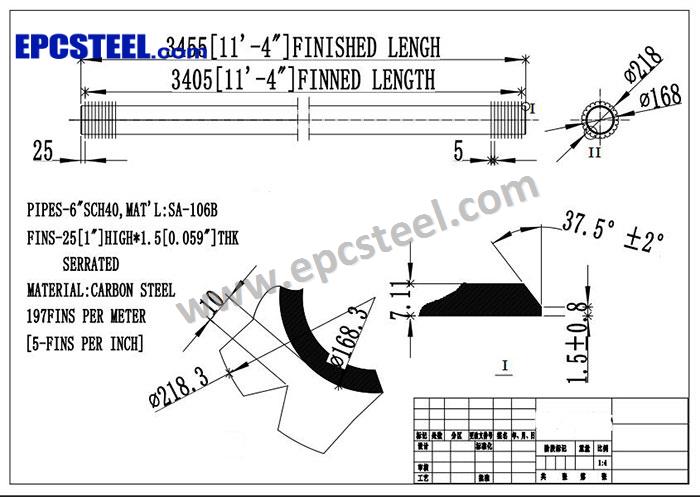

- Design the serrated fin tube, confirm the detailed parameter with the customers, which mainly includes the pipe length, OD, thickness, fin height, the number of fins within 1 meter and the serrate parameter.

- Cutting the pipe to fixed length. Customers have different need with the fin tube length, so we need to cut the steel pipe into different length. Normally the length of the fin tube is around 2-6 meter, but also some customers have need with the 18-25m. The maximum length EPC Steel can produce is up to 25m.

- Split steel coil into steel strap. The height of fins is equal to the width of steel strap, so we need to cut the coil into the strap according to different fins height.

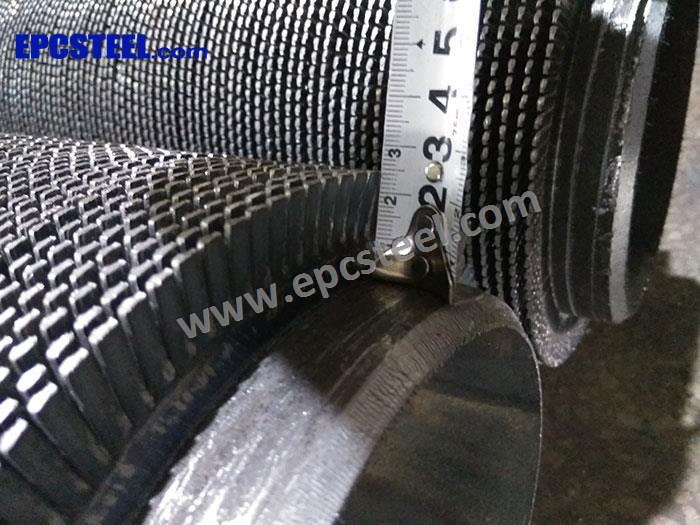

- Then we need to punch on the strip using the equipment as below. If we produce the solid fin tube, we don’t need to punch on the strip, just go to the next step. But if we produce the serrated fin tube, we need to punch on the strip. We can’t see big difference after the teeth punch. But after the punched strip been welded on to the pipe, due to the radius of highest point on the strip is bigger than lowest point, the stress on the highest point is also bigger than the lowest point’s, so the stress will pull open the serrate.

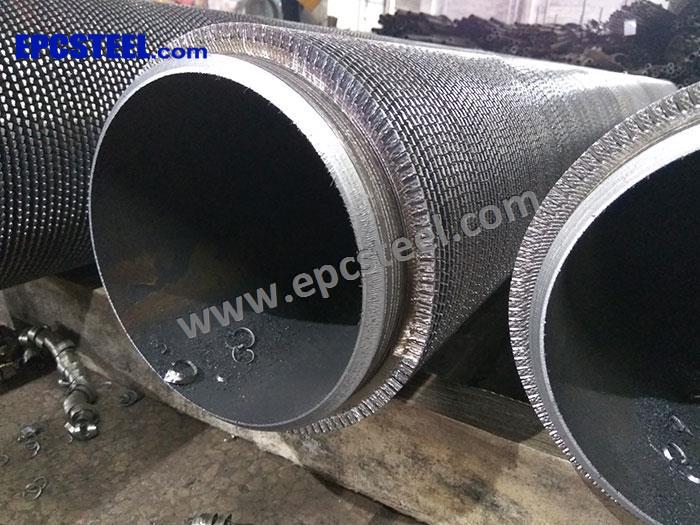

- Weld the steel strip on to the steel pipe. In order to control the number of fins within 1 inch or 1 meter, we need to control the pipe rotation speed and the strip feed speed. And normally the high frequency weld method is widely used in the manufacturing of welded fin tube.

- Then we need to bevel on the ends of tubes to make sure the fin tube is easy to weld on the project site.

- Inspection

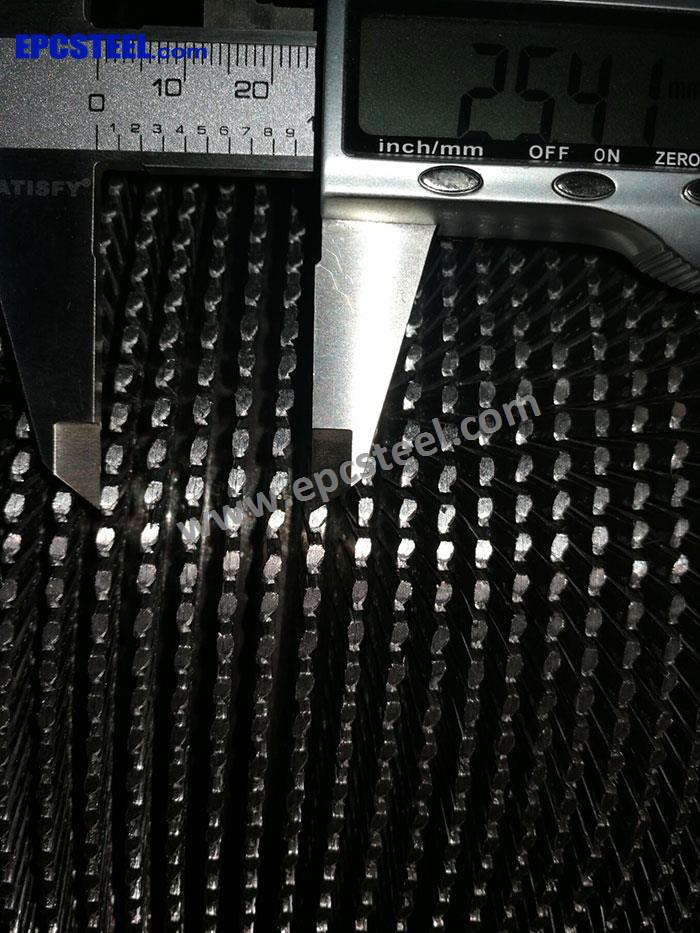

During and after the production, we need to inspect the fin tubes to make sure they are in strict accordance with the drawings. So we need to inspect the length of tubes, the OD, the tube thickness, the fin height, the serrate depth, the fin numbers within 1 meter and other parameter.

- Package

After the inspection results are sure to meet the customer’s requirements, then the goods will be packed into the wooden box or plastic bags with steel strip. We need to put the wooden plate between each piece of fin tube to ensure they will not contact with each other. Otherwise, the fins will be damaged.

III. EPC Steel Advantages:

Above process is the whole production process for the serrated fin tube. The key advantages that EPC Steel has are as below:

- Engineering and Design. Besides we can produce the serrated fin tube according to the customer’s drawings, we can also design the serrated fin tube according to customer’s actual usage and needs.

- The maximum length of the serrated fin tube can up to be 25meter

- Strict Quality Control. We have a set of method to make sure the production and inspection are in strict accordance with our ITP files.

If you have need with the serrated fin tube, welcome to contact with us. EPC Steel will try best to serve you with our experience and expertise.