What is 3PE coating pipe?

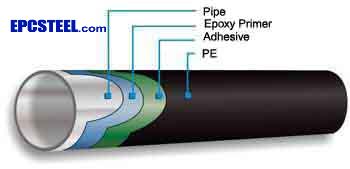

3PE coating pipe is short for “three layers structure polyethylene anticorrosion coating steel pipe”. There are three layers in this pipe coating structure:

- The first one: Epoxy layer (Thickness > 100um)

- The second one: Adhesive layer (Thickness: 170um~250um)

- The third one: Polyethylene layer (Thickness: 1.8~3.7mm).

What is the characteristic of the 3PE coating pipe

3PE coated pipe is the most advanced technology for the pipe anticorrosion. It puts together the advantage of the 2PE coating pipe and FBE coating pipe while at the same time avoids their weaknesses. Each layer of the 3PE coated pipe has its unique function in the coating structure.

- The epoxy layer is for the main anticorrosion function. It has strong connection with the surface of the bare steel pipe, favorable cathodic disbondment property, wide temperature range (-40℃-100℃) and low water-absorbing quality.

- The adhesive layer is to connect the epoxy layer and PE layer, whose main chemical composition is polyolefin. The polyolefin’s polar functional group can generate hydrogen bond or chemical bond with epoxy group of the FBE layer, making firm connection with the bottom layer. At the same time, the polyolefin’s nonpolar ethylene has affinity interaction with the PE layer, also generating favorable adhesive property with the face layer.

- The PE layer has favorable electrical insulation property, low water-absorbing quality and strong resistance to mechanical damage. This layer mainly has function of mechanical protection and anti-corrosion.

So 3PE coated pipe is a kind of composite system of these three layers with different functions, making the whole system is with all the functions to better protect pipeline.

What is the advantage of the 3PE coating steel pipes

Normal bare pipe will be corroded in the severe environment and its lifetime will be reduced, making the construction and maintainance cost very high. But due to every layer of the 3PE coating system has its good performance, the 3PE coated pipe can protect the pipe in the severe environment and extend its lifetime to 30-50 years even longer. it can significantly reduces the construction and maintainance cost for the pipeline. At the same time, the 3PE coated pipe has favorable thermal insulation property, the thermal losses is just 25% of the traditional pipe, saving a lot of energy cost during operation. At last, the 3PE coated pipe can directly be laid underground or in the water even directly in the frozen earth because of its good anticorrosion property and impact resistance property in the low temperature, no need to construct ditch.

What is the usage?

Due to the characteristic and advantage of the 3PE coated pipe, it is widely used in many kinds of applications such as oil & gas, water transmission, heat transmission, mining, fire-fighting, thermal power station, electric power, communication facilities, highway, chemical pharmaceutical, printing and dyeing and agricultural applications. And with its further development, the 3PE coated pipe will play more and more important role in the global development.

Related Products: